BASIC AC GENERATORS

Regardless of size, all electrical generators, whether dc or ac, depend upon the principle of magnetic induction. An emf is induced in a coil as a result of (1) a coil cutting through a magnetic field, or (2) a magnetic field cutting through a coil. As long as there is relative motion between a conductor and a magnetic field, a voltage will be induced in the conductor. That part of a generator that produces the magnetic field is called the field. That part in which the voltage is induced is called the armature. For relative motion to take place between the conductor and the magnetic field, all generators must have two mechanical parts – a rotor and a stator. The ROTor is the part that ROTates; the STATor is the part that remains STATionary. In a dc generator, the armature is always the rotor. In alternators, the armature may be either the rotor or stator.

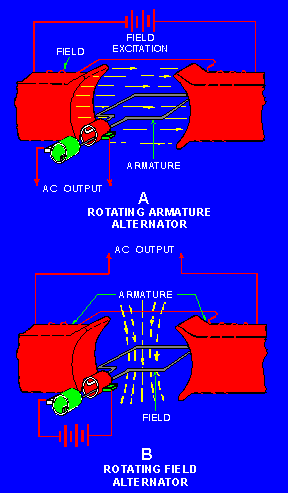

ROTATING-ARMATURE ALTERNATORS

The rotating-armature alternator is similar in construction to the dc generator in that the armature rotates in a stationary magnetic field as shown in figure 3-1, view A. In the dc generator, the emf generated in the armature windings is converted from ac to dc by means of the commutator. In the alternator, the generated ac is brought to the load unchanged by means of slip rings. The rotating armature is found only in alternators of low power rating and generally is not used to supply electric power in large quantities.

Figure 3-1. – Types of ac generators.

The rotating-field alternator has a stationary armature winding and a rotating-field winding as shown in figure 3-1, view B The advantage of having a stationary armature winding is that the generated voltage can be connected directly to the load.

A rotating armature requires slip rings and brushes to conduct the current from the armature to the load. The armature, brushes, and slip rings are difficult to insulate, and arc-overs and short circuits can result at high voltages. For this reason, high-voltage alternators are usually of the rotating-field type. Since the voltage applied to the rotating field is low voltage dc, the problem of high voltage arc-over at the slip rings does not exist.

The stationary armature, or stator, of this type of alternator holds the windings that are cut by the rotating magnetic field. The voltage generated in the armature as a result of this cutting action is the ac power that will be applied to the load.

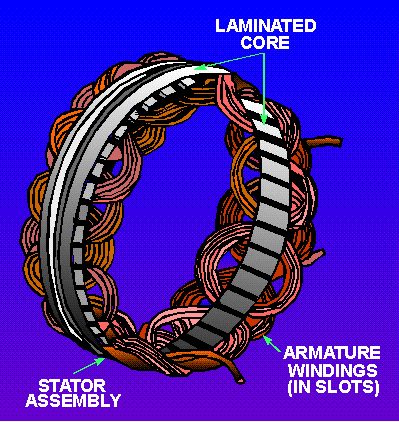

The stators of all rotating-field alternators are about the same.

The stator consists of a laminated iron core with the armature windings embedded in this core as shown in figure 3-2. The core is secured to the stator frame.

Figure 3-2. – Stationary armature windings.

![images[3]](https://everythingengines.files.wordpress.com/2012/09/images3.jpg?w=500)