I had the opportunity to learn the basic skills of riveting aircraft aluminum material and Safety Wiring Screws.

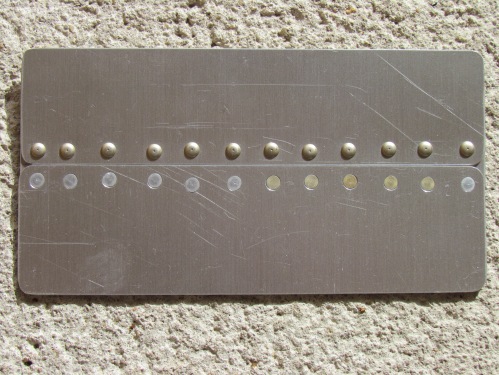

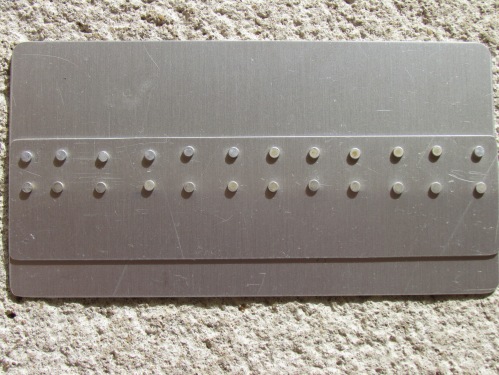

Riveting: The single lap splices are cleaned, sharp edges removed and the rivet holes are drilled. All burrs are removed and the material is prepared for riveting. Holes for countersunk head rivets are countersunk with a hand tool and the rivets are installed and “driven”. 100 degree heads are standard. A complete explanation is available in FAA AC-43-13 starting on page 4-14

Safety Wiring: In this example the safety wire is routed through the hole in the head of the first screw, twisted at 6-8 twists per inch and then one of the wires is threaded through the hole in the second screw, and so on. The wire is arranged such that each screw prevents the next screw from coming undone. The wire is also arranged so that the wire looping around the outside of the screw-head is held down by the wire passing through the hole in the screw. A complete explanation is available in FAA AC-43-13 starting on page 7-19